Features

8-CCD SENSOR WHEEL ALIGNMENT

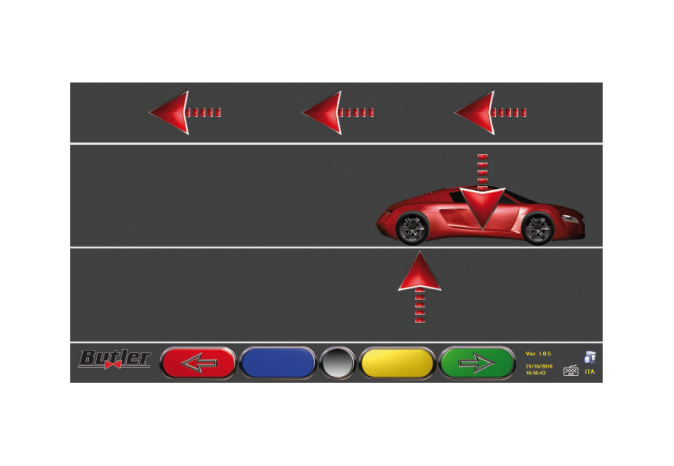

The system does not use any cables. The display of the program and the data is completely realized in 3D graphics. The user has access to all programs by simply pushing on 5 command keys displayed

on the screen that guide him step by step in the measuring.

The aligner is equipped with a powerful PC, a A4 printer and an useful compartment for wheel clamps deposit. Special supports on the side of the control unit permit housing andrecharging the measuring-head batteries when these are not used.

Infra-red transmission among measuring heads.

Bluetooth transmission between front measuring heads and control unit.

|  Synoptic LED signal repeaters on each measuring head. Contacts for battery charging. Pin monted on bearing. |

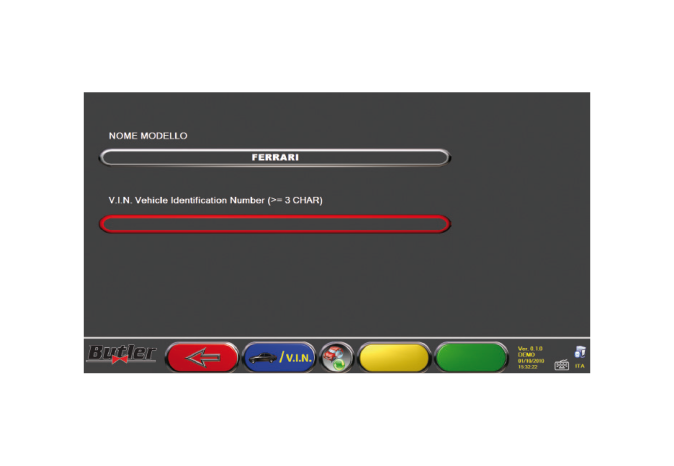

| Quick entering of vehicle by model or V.I.N. number |

| The steering procedure is carried out electronically, through the CCD sensors, so caster and king pin are measured with great precision. |

| Software operating under Windows that allows the management of: |

| A special Spoiler Program is automatically activated, through a simplified practical procedure, to perform the measurements on sport and tuned car bodies. |

| It is possible to measure wheel run out by moving the vehicle by only 30° (quick compensation in a little space)* without lifting the vehicle. |

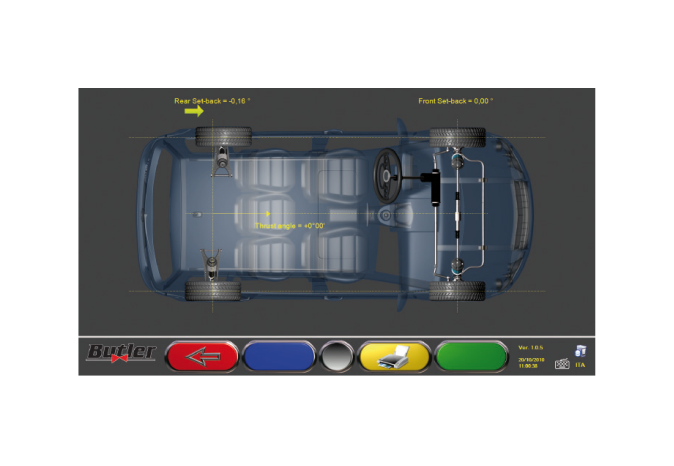

| The quick measurement of axle set back, wheelbase and track-width, may highlight any errors in the vehicles body and chassis symmetry. |