Features

LEVERLESS TYRE CHANGERS EQUIPPED WITH BUTLER EXCLUSIVE ACTIVE SENSOR SYSTEM

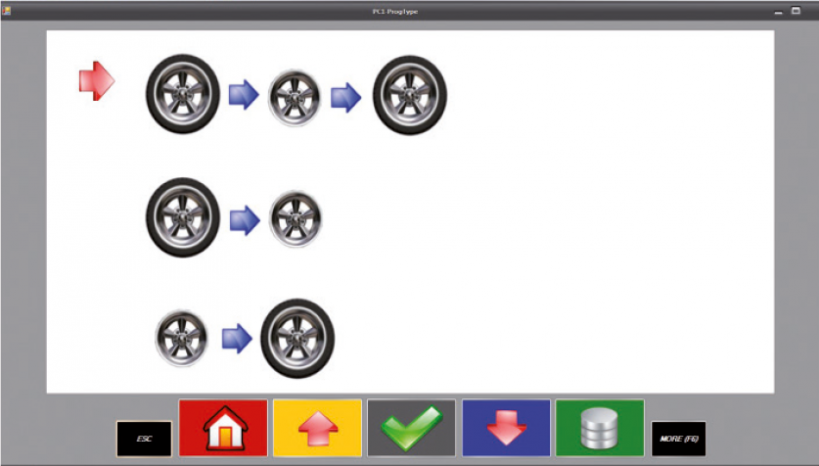

3 WORKING MODES Standard |

CAPTURE.4

| CAPTURE.3

| |

AUTOMATIC MODEConfirm wheel dimensions by the keyboard. Rotate the wheel and place the valve in start position. Press start button and the tyre changer is ready to work in automatic mode (Aikido program). Once the first wheel is done, the start position will be reached fast and automatically to repeat the job again and again. | ||

CAPTURE.3 | CAPTURE.4 | |

USER-FRIENDLY CONSOLESimplifies the operator’s learning process. With buttons for operating the rollers and tools. | ||

|  |  | ||

PC MANAGED OPERATION

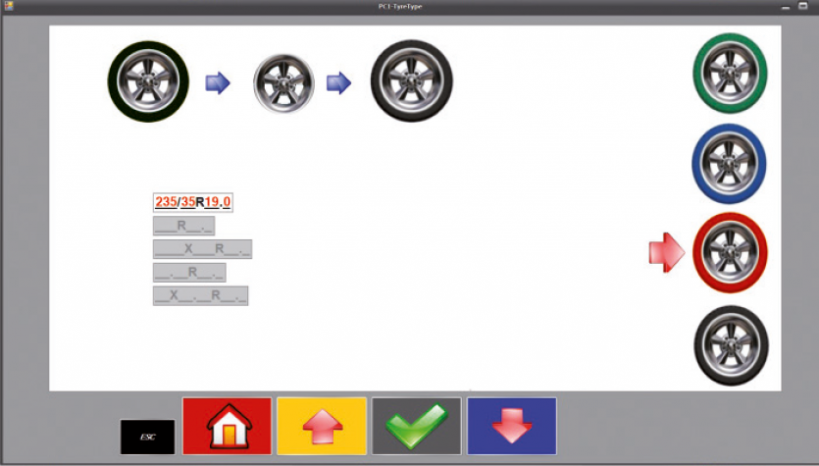

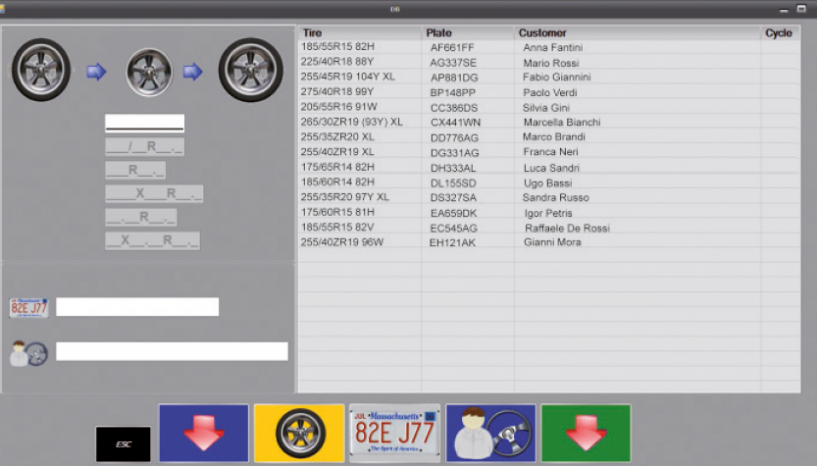

| TARGETED JOBWhen turned on, the tyre changer asks to choose the requested function:

The pre-set and dedicated cycle reduces working times | DATA BANKIt is possible to memorize up to 100.000 different wheels by:

DATA TRANSFERIt is possible to transfer data among tyre changers. This is particularly useful when working with many tyre changers:

Customized data and a quick training allow easy demounting of difficult tyres even by inexperienced workers. |

| ||

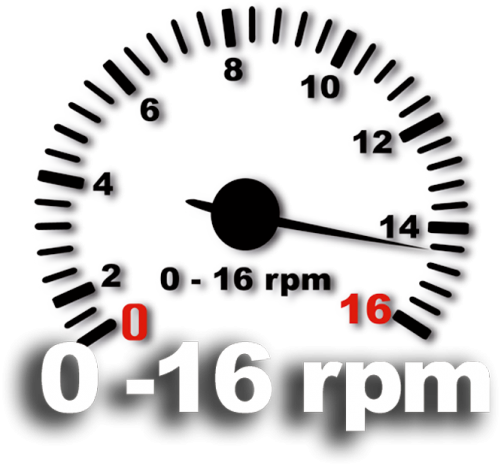

SUPER FASTOnce a wheel is clamped on the plate, demounting and mounting (complete cycle) varies from 55” to 75” including run-flat and UHP. Since 35” is the total time required to lift, lock, unlock and unload the wheel, the total time required for a complete cycle is as low as 90”-110” from floor to floor position. | INVEMOTORSpeed set by the operator, exactly as required. Inverter with governor to protect the tyre. |

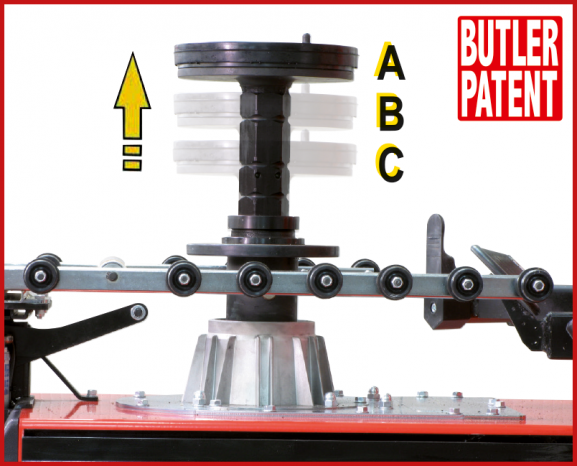

| EXTRA-GRIP CLAMPING DEVICE. THREE ADJUSTABLE WORKING HEIGHTSAllows clamping with just one cone. Gripping pressure is automatically increased during rotation. CONTROLLED HEIGHTThe tyre changer memorizes the height and calculates the working cycle consequently. In case the plate is wrongly positioned for a certain tyre, a change of height is automatically requested. |

| PATENTED LEVER-FREE TOOL. |

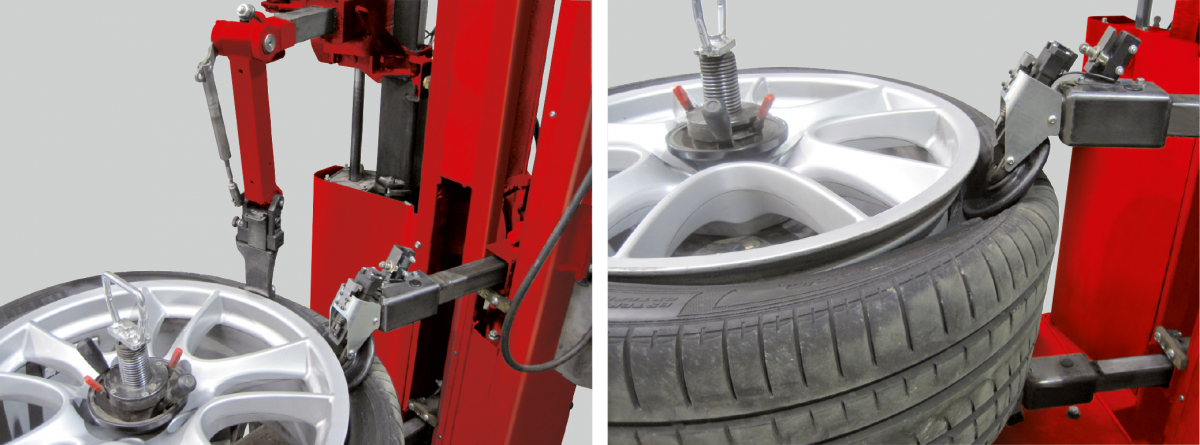

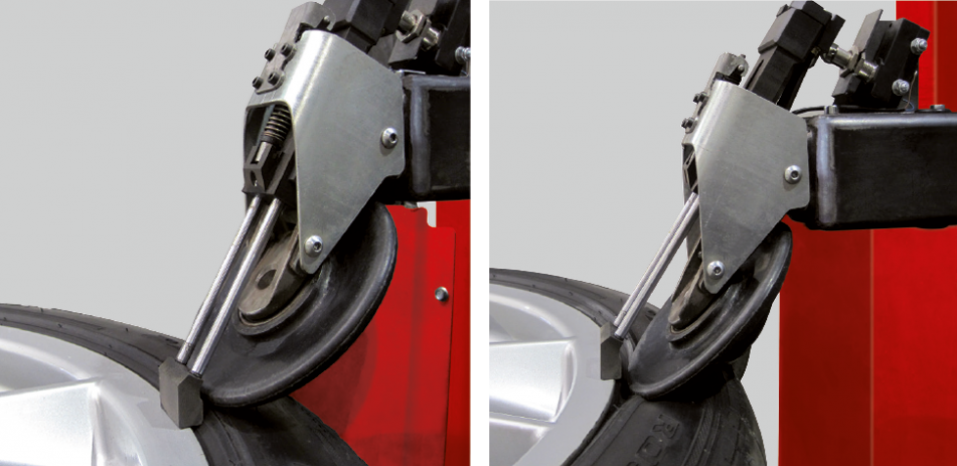

PNEUMATICALLY OPERATED BEAD BREAKER DISCS

Built in scratch-proof material for complete rim protection. The rim edge sensor allows the roller to move forward automatically, enabling it to work on the bead without damaging the tyre’s sidewall.

CAPTURE.4

The bottom tool works on the second bead, lifting it and removing the tyre from the rim. Also used for mounting.

|

VALVE SAFETYOnce the valve is placed at start position at the beginning of the cycle, the software will keep the valve in safe position during the entire job. |